So this is the last post of our blog officially ending the 22.201 Design Project with Professor Sullivan.

The team consisted of three members, Rachid Belhaj, Tobin Brown, and Kelly Chan. For our project we originally had anticipated on creating an LED cube programmed with the arduino. After failed attempts and trials of error with the idea, it ended up a mess and therefore we decided to scrap the idea. The details of our attempts are posted in the blog. To salvage our cube parts we decided to make a pig roast with the LEDs flickering to make it seem like a fire pit. We designed a solidworks part, which is also posted in the blog, to be 3d printed as our actual pig. After we got the 3D pig vetoed by Professor Sullivan in such short notice we just decided to have a part laser cut. It certainly doesn't look as cool as it would have been if it were in 3D but we got what we could.

In relation to the failed LED cube, it would have been neat if we were able to make one. I think if we were able to program the cube it light in the shape of a fire it would have looked at lot neater. We definitely have a better understanding of how to maneuver things when making the cube so that things don't fall on top of eachother. We'll take this experience and remember from our mistakes if ever we have to construct anything similar to it again.

Everything else, like the servo motor and stuff went off without a hitch. We had our setup done and were just waiting for our parts for the remainder of the week up until this point.

Overall, we think our project turned out to be a complete success! Everything worked as planned and everything is all said and done. We had a great time working with eachother, communication was spot on and our efforts were all answered with achievement.

- Team Us.

Design Lab Team Us

Friday, December 12, 2014

2D Laser Cut Part.

Today is the day the project is due. We literally JUST got word that our lasercut part was going to be done by 10AM today. Finally.

Later today is the Project Expo, we won't be able to attend for some of us have work during the expo and we need all of us to be there. So below, I have posted a few images of our cardboard part, a video of the part moving with the servo and also a video of the entire project in full swing. This is the first time we tested it with all the components together and hopefully it all goes according to plan.

Later today is the Project Expo, we won't be able to attend for some of us have work during the expo and we need all of us to be there. So below, I have posted a few images of our cardboard part, a video of the part moving with the servo and also a video of the entire project in full swing. This is the first time we tested it with all the components together and hopefully it all goes according to plan.

Tobin managed to snag some bread bag ties to attach the part to the motor.

SUCCESS!

Thursday, December 11, 2014

Overall Idea

Okay, I figured if we didn't get the part in time, I'd at least show what we had in mind with this project. Here I posted just a pencil and paper sketch of everything. There are two arduinos, a servo, LED lights, and a pig. The pig is the object we wanted to have 3d printed/laser cut. on the top is listed with the things mentioned above and below is how we were going to set everything up. The servo would rotate the made part above the pulsating LED lights to make it look like its roasting.

Cheesy, we know.

Here is a link to our google drive which contains the two solidworks parts we made for this project:

https://drive.google.com/folderview?id=0Bw29l4qYnW1QX0gzU3hqSXBQRUE&usp=sharing

Cheesy, we know.

Here is a link to our google drive which contains the two solidworks parts we made for this project:

https://drive.google.com/folderview?id=0Bw29l4qYnW1QX0gzU3hqSXBQRUE&usp=sharing

Bad News.

SO we just got some bad news about our 3d part. We resubmitted it a few days ago and just today, we got word that it can't be printed. Our only option now is to have it laser cut out of cardboard.

It's just an outline of the original idea. It's no more than 5 inches long. We need this part ASAP.

Servo.

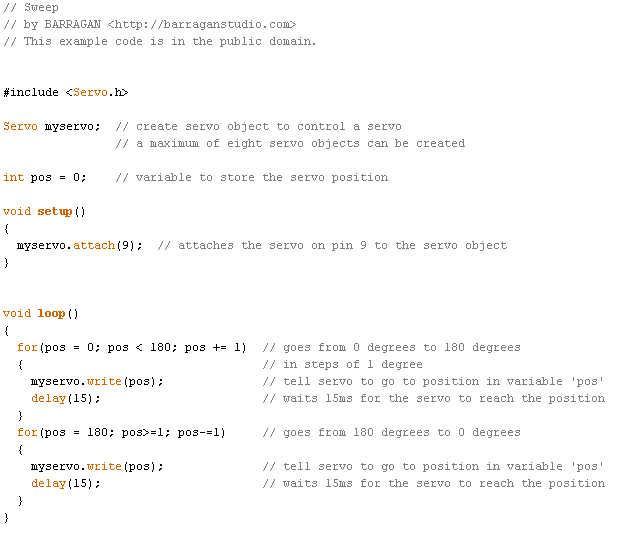

Tobin, coded and set up his arduino to run a servo motor.

Here's is the code he used, it was found in an example on the arduino program on one of the school computers.

It runs beautifuly. It's just what we need to make our part rotate.

Here is a video if it below:

Here's is the code he used, it was found in an example on the arduino program on one of the school computers.

It runs beautifuly. It's just what we need to make our part rotate.

Here is a video if it below:

Tuesday, December 9, 2014

Crunch time.

Okay so, we had our request go in December 5th, it's now the 9th and we still hadn't got any word.

With the project due Friday, things are getting worrisome.

If we don't have it by Wednesday, tomorrow, we're just going to have to forgo the 3D printed part and make one out of other materials. It won't look as cool, but it's something, a prototype.

Hopefully it all works out.

*Fingers Crossed*

With the project due Friday, things are getting worrisome.

If we don't have it by Wednesday, tomorrow, we're just going to have to forgo the 3D printed part and make one out of other materials. It won't look as cool, but it's something, a prototype.

Hopefully it all works out.

*Fingers Crossed*

IDEA.

So after looking at that ferocious lighting effect, it started to look like a flickering fire to me. With that, I figured we could make use of that imagery and roast a pig! We could 3D print a pig on a rod and attach it to a servo to make it rotate on top of the LEDs.

Okay, I must admit, it probably wasn't the coolest idea, but with the failed LED cube and due date due on this project, I thought it made sense.

So after talking to over with the rest of the group, we decided to give it a go. Tobin used Solidworks to make the part and it turned out pretty fantastic.

Okay, I must admit, it probably wasn't the coolest idea, but with the failed LED cube and due date due on this project, I thought it made sense.

So after talking to over with the rest of the group, we decided to give it a go. Tobin used Solidworks to make the part and it turned out pretty fantastic.

We sent in the request to have it printed on Friday, December 5. 2014. Hopefully we get it soon.

Subscribe to:

Comments (Atom)